When you purchase through links on our site, we may earn an affiliate commission.Heres how it works.

In today’s rapidly advancing technological landscape, digital transformation is a key driver of innovation across many industries.

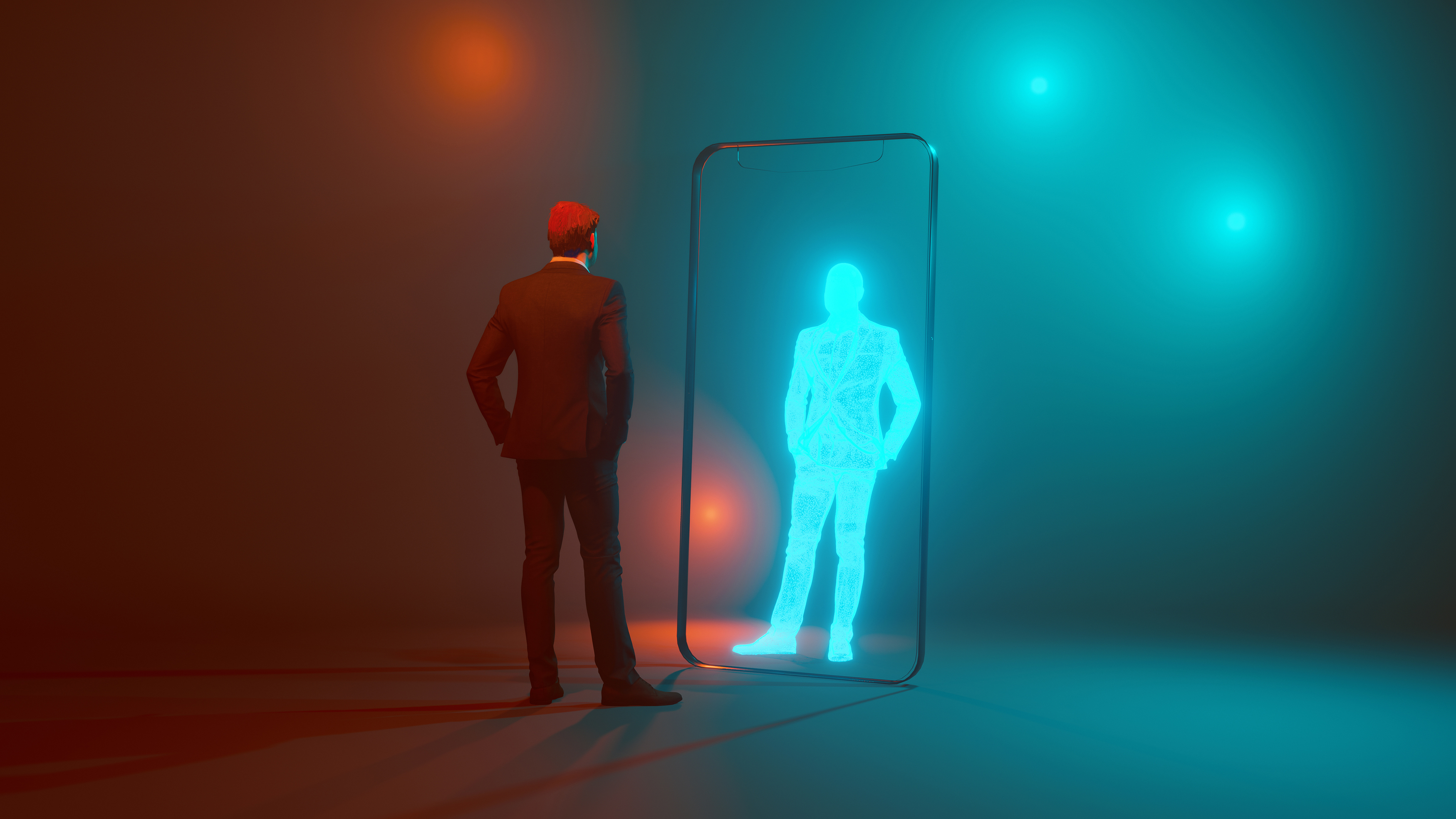

One of the most impactful technologies leading this revolution is the digital twin.

This is a real-time virtual model that replicates a physical object, system, or process.

It continuously receivesdatafrom its physical twin, creating a dynamic, up-to-date digital replica.

Product Manager for Professional Visualization at PNY Technologies EMEA.

What is a Digital Twin?

One of the key features of a digital twin is its ability to simulate future scenarios.

These early models laid the groundwork for the development of the digital twin concept.

Today, digital twins are more sophisticated than ever before.

They can process vast amounts of data in real time, enabling detailed simulations and advanced analytics.

What are Digital Twins used for?

Digital twins are incredibly versatile and have foundapplicationsacross many industries.

Below are some of the primary use cases for these tools and how they are transforming different sectors.

Manufacturing

Manufacturing is one of the largest users of digital twin technology.

Additionally, digital twins are invaluable for predictive maintenance.

Personalized healthcare, in particular, benefits from digital twins.

This allows them to visualize the surgery and plan for potential complications, improving the chances of successful surgery.

Similarly, pharmaceutical companies use digital twins to simulate how drugs interact with the human body.

This helps them develop new treatments more quickly and efficiently by testing drug reactions virtually before conducting human trials.

Digital twins are also instrumental in disaster response planning.

One of key aspects of digital twins in aerospace is their ability to inform predictive maintenance.

This reduces the risk of in-flight issues and lowers operational costs.

Airlines are also using digital twins to simulate flight conditions and boost fuel efficiency.

For example, wind farm operators use digital twins to track the performance of individual turbines.

This data helps operators identify underperforming turbines and adjust to maximize energy production.

Digital twins also help energy companies manage grid stability.

Below is a detailed explanation of each phase in the development process.

Data collection

The first step in building a digital twin is collecting data from the physical object or system.

In some cases, historical data may also be used to model how the object has performed over time.

The more data is collected, the more accurate and detailed the digital twin will be.

This is often built using3D modellingsoftware or computer-aided design (CAD) tools.

The complexity of the model will depend on the nature of the object being reproduced.

This connection ensures that the digital version evolves as the physical object changes or moves through different operating conditions.

In many cases, real-time data is transmitted via IoT platforms and processed in thecloud.

By running these simulations, businesses can prepare for potential challenges and make more informed strategic decisions.

This includes tracking wear and tear, repairs, and upgrades.

Regular updates ensure that the digital twin remains a reliable tool for monitoring and simulation.

These updates allow engineers to make accurate predictions about future maintenance needs and performance.

They reflect the current state of their physical counterpart, using data gathered from sensors and other sources.

This connection allows digital twins to provide accurate insights, predict future behaviors, and make real-time decisions.

For example, a simulation might help design a new product, testing it virtually under various conditions.

However, once the simulation ends, its static.

A digital twin, on the other hand, remains active, continuously mirroring the physical products lifecycle.

The process involves setting up data collection through sensors, building the digital model, and validating its accuracy.

Creating a digital twin isnt just about initial setup; its an ongoing effort.

A digital twin must be updated and maintained to keep it in sync with the physical world.

We’ve featured the best data visualization tool.

The views expressed here are those of the author and are not necessarily those of TechRadarPro or Future plc.