The fact that it features excellent laser engraving and cutting all add to the appeal.

Tool swaps are straightforward, and despite a few quirks, they come together to add great value.

From the moment the printers arrived, both were quickly unpacked, set up and fired into action.

I found this was actually made to simplify tool head changes.

Managing filament takes a little getting used to.

Beyond printing, the laser module also performs well, offering sharp, consistent engraving.

TPU can still be a bit fiddly, as ever, but overall usability has improved over earlier systems.

What’s most exciting is how the machine’s strengths combine.

An individualised review of the H2D will inevitably follow.

The laser edition is one of two new H2D machines launched by Bambu Lab.

The dual nozzle tool head is a smart approach to design.

With two nozzles, additional materials can be loaded without unloading or retracting, making multi-material prints much faster.

Adding the laser head to the front of the printer transforms it into a high-speed laser cutter and engraver.

The digital cutter and plotter are the least familiar territory for me, though I have some experience.

Compared to other multi-feature machines, it’s extremely user-friendly.

Heated and actively ventilated chambers are now standard for advanced materials.

For high-temperature materials like ABS or nylon, the chamber is sealed, and warm air recirculates it.

For cooler filaments like PLA, top-mounted vents pull in and exhaust air.

Where many machines handle each tool head in isolation, the H2D supports multi-process alignment.

I’m hoping a Mac Suite will arrive soon.

Precision remains a key feature.

The extruder now uses brushless servo motors, offering finer control over torque, speed, and positioning.

The AMS system has evolved again.

AMS Gen 2 functions as both a dryer and a storage unit.

It includes live humidity monitoring and keeps filaments sealed when not in use.

As mentioned, this review is focused on the H2D Laser Edition, which is the fully featured version.

These can be added to the base H2D as upgrades.

In practice, these results are a noticeable improvement in print quality.

Running initial single-filament tests, quality and speed matched the X1C closely.

Actually, TPU needs to be fed through that nozzle.

Printing models like lamps, shoes, and GoPro mounts, the quality and finish were consistently excellent.

This level of precision is further supported by the machine’s calibration plate, allowing users to fine-tune alignment.

That said, it’s not all seamless.

PLA support material, if not perfectly dry, caused problems during testing.

The machine’s complexity also introduces occasional issues.

It’s effective but perhaps a little overcautious at times.

TPU loading is also a bit fiddly.

TPU must run through the right nozzle, meaning the AMS must be disconnected.

Each pair takes around 7080 hours to produce, and the machine handles the extended prints without issue.

Safety features help catch issues early, typically triggered by the appearance of loose filament strands of filament.

It’s fast and relatively intuitive, making it ideal for craft work and creating stickers.

Then there’s the laser module, which is more involved but still easy to set up.

Bambu Suite is well-designed and easy to use, although, at present, it is only PC based.

It lets you assign engraving or cutting paths, split object sections, and quickly apply functions.

One note: Bambu Suite is currently PC-only.

A Mac version is yet to be announced.

During the test, I did try linking LightBurn on Mac, but it wasn’t compatible during testing.

When it comes to using the output, the 40W laser does prove to be powerful and incredibly accurate.

This was a consistent pattern across various test materials.

Fill and line engraving, on the other hand, were immaculateclean and accurate, even on intricate paths.

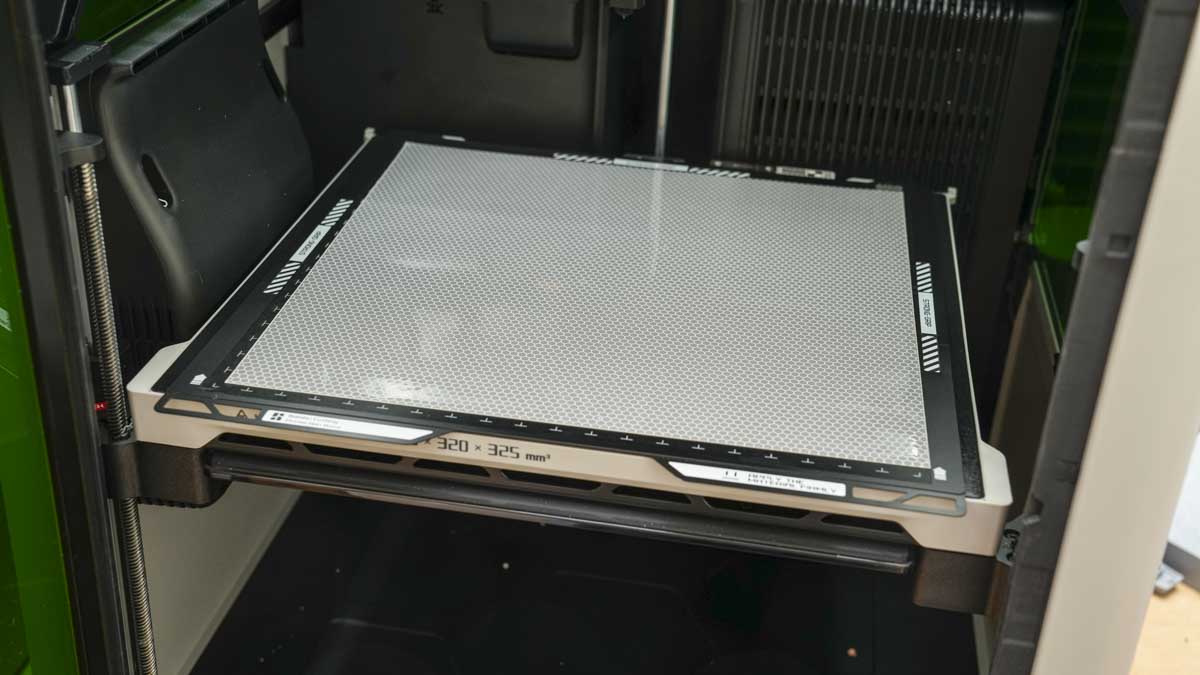

One limitation is the laser work area.

For small businesses, design prototyping, or hobby work, though, it’s more than enough.

There’s also currently no rotary option, so all material must lie flat.

Workflow complexity increases with advanced materials, especially during tool swaps or when managing dry filament feeds.

For small to medium-sized multidiscipline projects, it worksand works well.

None of it is especially complicated, but it does require some careful setup.

Once configured, the results are superb.

The machine feels like a continuation of what CEL-UK started with the RoboxDual before pivoting to B2B.

One highlight for workshop use is the inclusion of laser-safe windows.

With proper extraction, this can be used safely in shared spacessomething not always true with other engravers.

With a flat top, these units could be neatly stacked while still allowing access to the filament bays.

As it stands, I’ve had to improvise with three units awkwardly arranged on a rapidly disappearing worksurface.

What stood out most during testing was reliability.

Otherwise, the AI will stop things and make you clean it out.

Accuracy with PLA is good but takes a leap when paired with the Vision Encoder platform calibration.

Should You Buy the Bambu Lab H2D?

While there are some workflow issues, the overall design works incredibly well.

You need a single machine with multidiscipline.

You need high-quality multi-material printing.

Don’t buy if…

Laser engraving is the primary focus.

You only need single-filament prints.

If you’re not planning to use multiple materials, the more affordable X1C remains a great choice.

It handles single-filament work just as fastif not fasterand with identical quality.